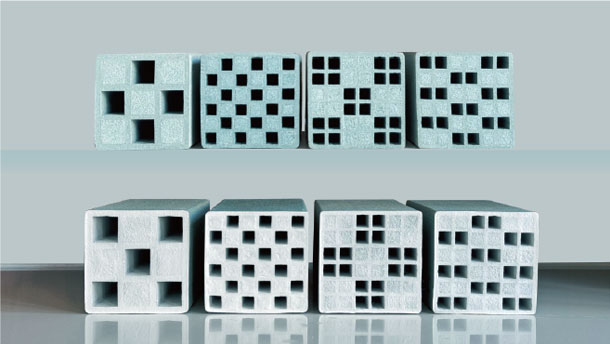

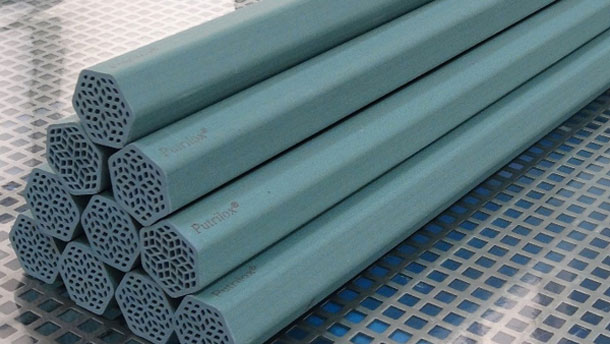

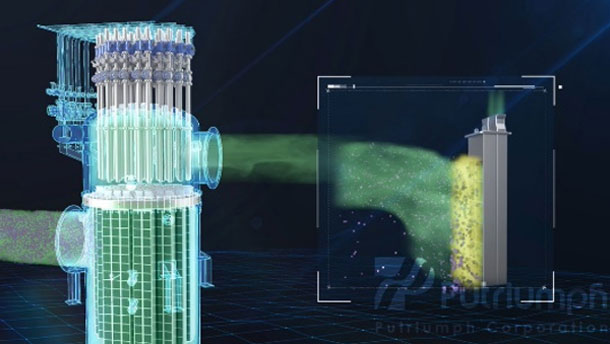

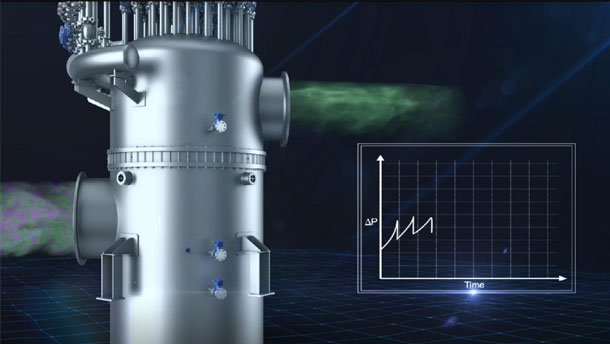

Shandong Putriumph Flow Technology Co., Ltd. is an enterprise specializing in the application of silicon carbide membrane and filtration system. Our services include high-temperature gas filtration, fine filtration, material purification etc. We can provide the design, production and after-sale service of automatic blow-back filtration systems for ultra-high temperature, high pressure and high flow rate dusty gas conditions.

From basic material to application, from pilot experiments to industrialization, Putriumph focuses on the whole chain of research management.

Since its establishment, Putriumph has won many honors such as “High-Tech Enterprise”、“Specialized and Sophisticated SMEs”、’One enterprise, one technology’ R&D center and has dozens of patented technologies.

From basic material to application, from pilot experiments to industrialization, Putriumph focuses on the whole chain of research management.

Since its establishment, Putriumph has won many honors such as “High-Tech Enterprise”、“Specialized and Sophisticated SMEs”、’One enterprise, one technology’ R&D center and has dozens of patented technologies.